Why AMOLEDs aren’t be used in industrial applications?

Blaze Display Technology Co., Ltd. | Updated: Nov 27, 2018

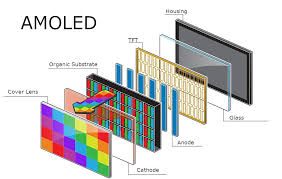

Certainly, AMOLED displays have many advantages compared to TFT LCDs: Lighter weight, thinner profiles, wider temperature ranges, and better overall optical performance. Additionally, AMOLED power consumption can be as efficient as TFT LCDs, and oftentimes more efficient for certain applications. Their power efficiency can even make display-always-on modes possible for uses like peek-able display windows. However, the key advantage of AMOLED displays over TFT LCDs is that AMOLEDs can be made flexible with the use of polyimide substrates. This incredible flexible feature enables the development of bendable and foldable displays, which could unlock unlimited potential for technology advancements, such as conformal displays. So far, AMOLED display technology seems to be the only feasible gateway towards displays working like newspapers or magazines, as we saw in Si-Fi movies just a few decades ago. Given these AMOLED advantages, some forward-thinking industrial, medical and military application engineers asked if AMOLED technology is available for their products. Their enthusiasm for newer technology is fully understandable. However, AMOLED technology is just not “there” yet and may take several years before it can be considered a good solution for their applications. Here are some reasons why:

1.High Cost

TFT LCD technology has been around for two more decades than AMOLED technology, allowing far greater time to improve the manufacturing processes and materials, reducing production costs. AMOLED production processes are still quite complicated and have a steep learning curve. If a typical TFT LCD fab has an 85% yield rate, without changing anything it could have an initial 0% yield rate on AMOLEDs. To be successful, manufacturers must invest a significant amount of money on research, development and capital investments to solve various unique AMOLED issues, such as particle, encapsulation, Mura, mask cleaning, pixel repairing, and aging. Right now, other than a few Samsung AMOLED fabs, most AMOLED fabs are brand new, working through their debugging phases, and under heavy depreciation pressure. Therefore, the NRE/NRT prices for AMOLEDs are still quite high.

2.Less Support

Due to major investment costs and complex processes, AMOLED fabs are focusing on a handful of key customers. Their typical customers are those within the consumer electronics industry with high production volumes, such as major smartphone manufacturers. Once their production processes are established for one project, fabs don’t want to switch masks and processes for other projects as this can shut down production lines for an unknown period of time. Industrial applications typically have low production volumes, so AMOLED fabs aren’t often willing to manufacture for them.

3.Unknown Reliability

So far, AMOLED reliability validation has focused on major consumer electronics categories – such as smartphones – whose average lifespan is a mere 2 years. Typical industrial applications demand 5 years of lifetime, while some medical applications may request as much as 10 years of lifetime. There are also many environmental unknowns for industrial applications that could affect reliability: Image sticking, solar effects, high humidity, and high temperatures. Currently, some flexible AMOLEDs are limited to only 100 times of bending. It will take years to meet the robust and rugged requirements of industrial applications.

4.Frequent EOL

Current AMOLED processes and materials are developed and designed for consumer electronics. All these are constantly in the optimization phase to improve yield and reduce cost. EOLs are expected to happen frequently due to die shrinking, material changes and process optimization. Industrial applications take a long time to develop and to achieve the right quality standards. Therefore, it’s likely that EOL would happen even before mass production.

Because AMOLED technology is still several years away from being used in industrial applications, proven TFT LCD technology along with its derivatives will continue to be the primary technology utilized. This is not unlike the lag when TFT LCD technology replaced CRTs, where industrial applications didn’t start adopting TFT LCD technology for another 3 to 5 years after consumer electronics applications.