LED Backlit

Blaze Display Technology Co., Ltd. | Updated: Nov 27, 2018

Led Backlit (Back Light) is the liquid crystal display (LCD) light source provider, LCD itself does not emit light, the performance of the led backlit determines the visual sense of the lcd screen outside, tft display because of its thin thickness, light weight, easy to carry and other advantages, in recent years the demand has increased rapidly, has accounted for a certain proportion of the CRT market; With the improvement of tft display manufacturing technology, large size and low price, the advantages of led backlit in lightweight, thinning, low energy consumption, high brightness and cost reduction are becoming more and more important in the future market demand.

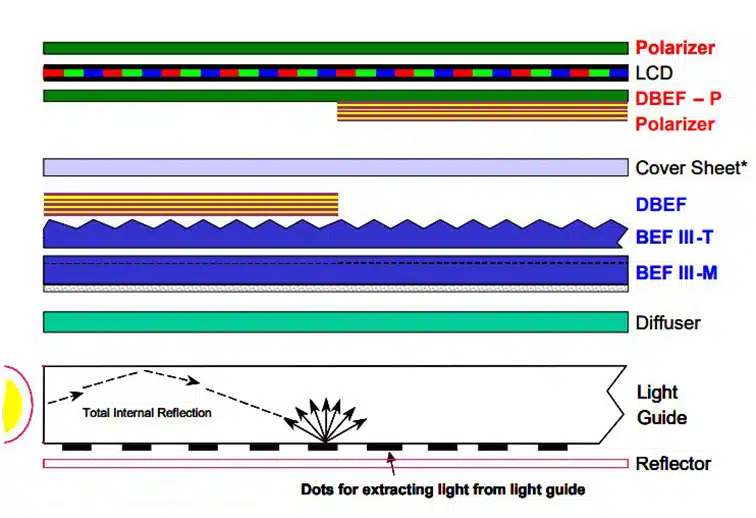

The structure of the led backlit

The led backlit occupies a very important position in the display module, and the tft screen cannot emit light by itself, and the light displayed is provided by the led backlit. The led backlit determines the brightness and some optical parameters of the display module. It consists of DBEF, BEF, Diffuser, Light guide, LED bar and Reflector.

Plastic frame in led backlit

The plastic frame plays the role of supporting and fixing all membranes and components, the main ingredients: polycarbonate (PC), TiO2, generally white, because white can reflect light well and reduce the loss of brightness.

Bezel

The main function of Bezel is to increase the structural strength of the product and protect the lcd display and other components in the liquid crystal display module. Bezels are widely used on industrial displays, bringing better performance to tft displays and adapting to more usage environments.

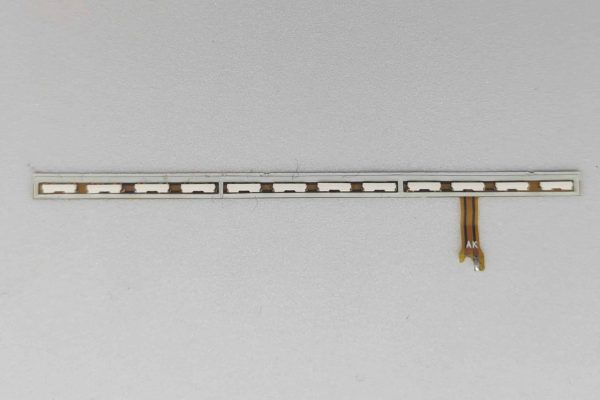

LED light bar

The LED lamp bead provides the light source for the led backlit, and the brightness of one LED lamp bead is limited, usually many LED lamp beads are used, for example, there are 14 LED lamp beads in the 5.5-inch led backlit lcd, the LED light bar is the LED lamp The beads are fixed and attached to an FPC.

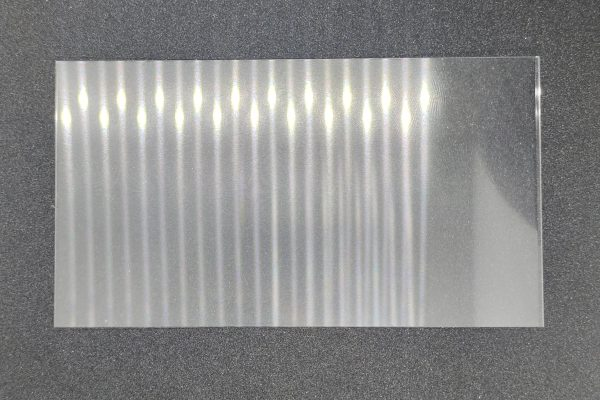

Light guide plate in led backlit

The light guide plate is an important part of the led backlit, and there is a PC (polycarbonate). in contrast to PMMA (acrylic), the light guide plate deflects the light emitted by the LED by 90° and evenly distributes the light throughout the display.

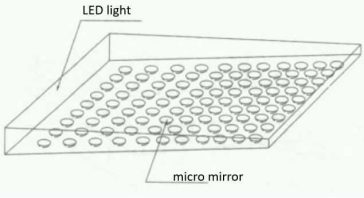

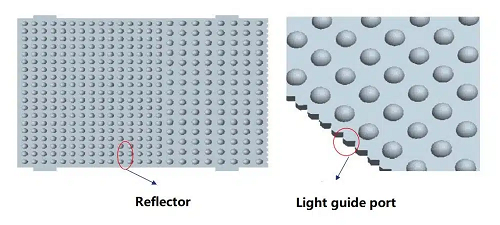

What is light guide plate in the led backlit?

The light guide plate uses ultra-precision processing technology to make a fine optical mirror on the bottom of the light guide plate, so that the light parallel to the light guide plate can be reflected to achieve the effect of changing the horizontal light into a vertical light. The specific production steps are to finely process the injection molded core into a round micro mirror (Micro mirror), and then use the plastic injection molding machine to make the light guide plate. The light guide plate is the most important optical device in the backlight. If the light guide plate is abnormal This will lead to problems such as picture color shift, uneven color temperature and so on.

The principle of the light guide plate: use the sawtooth structure of the light incident part and the dots at the bottom to refract or reflect all the light emitted by the LED, change the direction of light propagation, and use the light efficiently. The position in contact with the LED lamp beads has high brightness, and the position away from the LED lamp beads has low brightness. Therefore, in order to ensure uniform brightness of the entire light guide plate, a sawtooth structure is adopted at the light incident part of the LED, and the dots are sparse. Then gradually increase the mirror density.

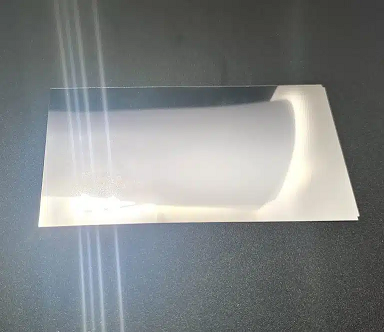

Diffuser in led backlit

The diffusion film can refract the light irregularly, so that the uniformity of the surface light source is better. The use of double-layer diffusion film effectively reduces or eliminates some undesirable phenomena, such as Newton’s rings, interference fringes, optical film scratches, etc. However, the thickness is thicker in design and the cost is increased. Since many upper brightness enhancement films now have diffusion particles, the upper brightness enhancement film and the upper diffusion film are combined into one. The thickness is reduced, and the cost is reduced. At present, the backlight design basically only uses the lower diffusion film.

BEF in led backlit

The direction of light guide plate light source is not concentrated on the front of the light guide plate, so the brightness requirements can not be achieved in the field of view of the LCD, the direction and diffusion angle of the light source must be corrected, so that the light source is concentrated in the required direction as much as possible, and the light enhancement film is used as an important component of angle correction and light collection effect.

Reflector

The reflector reflects the light emitted from the dot surface of the light guide back to the inside of the light guide to reduce the loss of light energy Lose.

Reflectors are divided into three categories:

Multilayer polymer type – ESR

• The reflectivity is the best, reaching 98% or more

, the price is also the most expensive.

Silver-plated reflective film.

• The reflectivity is slightly inferior to ESR, and it is made into a backlight

The brightness of ESR is reduced by 8~10%,

Affordable price.

White reflective film

• Low cost, reflectivity can be on par with silver-plated reflective film, and the price is only half of it.

Conclusion

The led backlit is an important part of the tft screen, because the structure is complex and composed of many film materials, it is also the most prone to abnormal parts in the led backlit lcd, if your display screen appears dots, local darkening, rainbow-like rings then It’s all about led backlit.