Differences Between FFCs and FPCs

Blaze Display Technology Co., Ltd. | Updated: Nov 27, 2018

Flat Flexible Cables (FFCs) and Flexible Printed Circuits (FPCs) are two types of flexible cables commonly used to connect devices together when working with electronics. As flexible cables, both are built to easily make connections with more flexibility than traditional rigid cables. FFCs and FPCs are often confused based on their similar appearance, but both serve different purposes and are better suited for certain projects.

FFCs and FPCs are both types of flexible cables. The main difference is that FFCs contain basic wires, suitable for simple connections. On the other hand, FPCs are like miniature circuit boards on a flexible sheet, enabling complex connections and additional functions for space-saving applications.

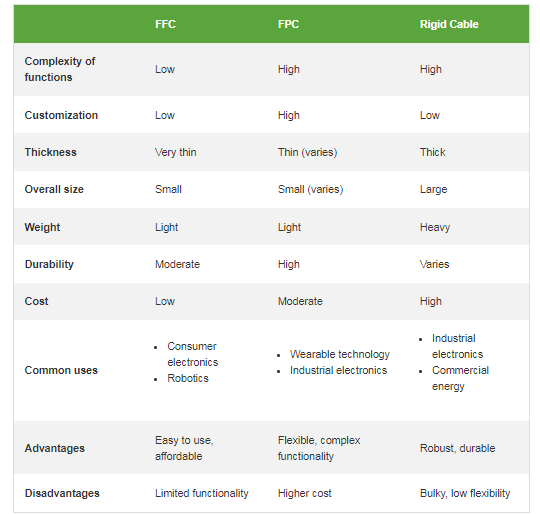

FFC vs FPC vs Rigid Cable Comparison Table:

Choosing Between an FFC and FPC

When choosing between an FFC and an FPC for a project, it's important to consider the factors below about your project before deciding which flexible cable to use.

Complexity of functions

l FFC: Suitable for making simpler connections where high flexibility is needed, but the circuit does not require intricate routing.

l FPC: Ideal for performing functions that require complex circuit designs with intricate routing, multiple layers, or additional electrical components.

Movement

l FFC: Excellent for applications requiring frequent bending.

l FPC: Suitable for applications where the circuit must fit into tight or irregular-shaped spaces and endure dynamic movements.

Budget

l FFC: Generally more cost-effective due to their simpler design.

l FPC: More expensive due to the design complexity and required materials.

Environmental conditions

l FFC: Typically used in environments with moderate thermal stress. Polyester-based FFCs can handle standard conditions, but polyimide-based FFCs offer better thermal stability.

l FPC: Well suited for standard or harsh environments, including high temperatures, chemical exposure, and mechanical stress.

Space constraints

l FFC: Suitable for applications where space is limited, but the flexibility of the routing is relatively straightforward.

l FPC: Excellent for tight spaces due to their ability to conform to various shapes and sizes.

Conclusion

FFCs and FPCs are both made to connect together devices in projects that require a flexible, bendable cable. Past this, each cable has strengths that better suit different applications. FFCs are best for applications that require quick, straightforward 1:1 connections, whereas FPCs are best for those that require more complex and specific functionality.