The Zebra Strips and FPC/FFC Connectors for LCD Displays

Blaze Display Technology Co., Ltd. | Updated: Nov 27, 2018

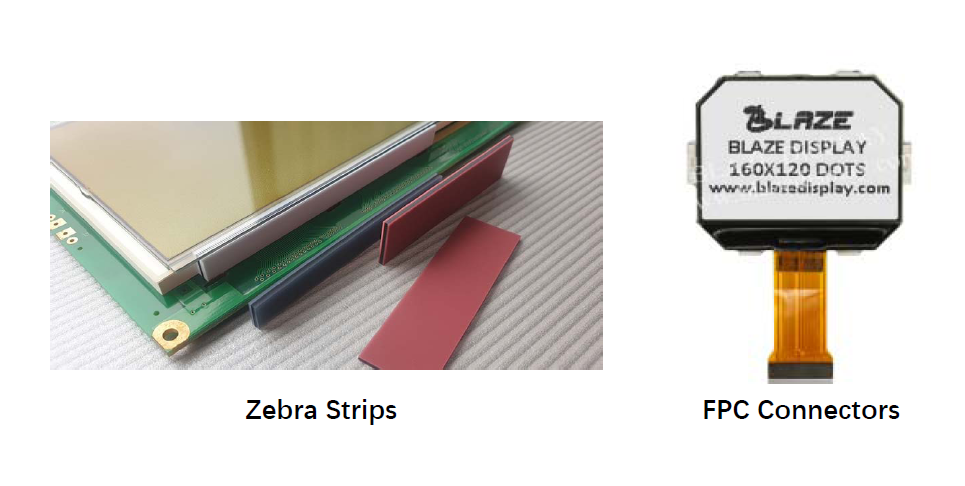

Zebra Strips (Elastomeric Connectors)

Elastomeric connectors, also known as ZEBRA strips, are a common connection type for LCDs with surface mount connections. A ZEBRA strip connector is comprised of a malleable insulation strip with alternating conduction lines and can be used as a substitute for a hardwire connection. These connectors get their name from their alternating conduction lines that appear as stripes, similar to a Zebra.

ZEBRA strips are positioned between a display’s connection ports and its controller. They then require a bezel to ensure a proper connection with the display. Once the bezel has been applied, the ZEBRA strips compress against an LCD’s surface mount connection ports. The resulting pressure from the bezel allows for a solid connection between the conductive strips and the display.

This connection type is a good option for testing and prototyping displays as there is no need to permanently connect pins to the display. ZEBRA strips are also a good option for thin, compact LCD and PCB designs. For example, if limited space is available within the enclosure, a ZEBRA strip can be used as an alternative to metal pins or ZIF connectors. ZEBRA connectors can also often be a cheaper alternative to other connection types.

FPC/FFC Connectors

Flexible printed circuit (FPC) and flexible flat circuit (FFC) cables (hereinafter both interchangeably referred to as “FPC” or “FPC Cable”) are widely used connectors that provide access to the internal circuitry embedded in the display. Such connectors are standard in laptops and mobile phone displays.

FPC cables reduce the amount of area required by pins to interface with a display and can be integrated into PCB with minimal space and complexity by routing the signals through this cable.

FPC cables are directly routed to the embedded liquid crystal driver and the internal circuits required to drive the display. To access the contacts on an FPC, a ZIF connection port can be used to hold the cable in place and prevent damage to circuitry. The end of an FPC cable is placed into a ZIF connection port and locked into place by a clasp or plastic holder.

The flexibility of an FPC cable is ideal for compact devices. The cable is made of a flat, bendable material that insulates the conductive wire connected to the LCD. The conductive leads to the display are heat sealed between durable insulative strips.

While FPCs are bendable connectors, it should be noted to avoid fully compressing the cable to prevent damage to its internal circuitry.

The spacing between each metal contact on the ribbon cable is called the pin pitch. The pin pitch for a display’s FPC cable can vary and is specified by each display. A common pin pitch for a display is 0.5 mm, but can range from 0.3 mm to 1.0 mm.