The Through Holes & Metal Pins Connectors for LCD Displays

Blaze Display Technology Co., Ltd. | Updated: Nov 27, 2018

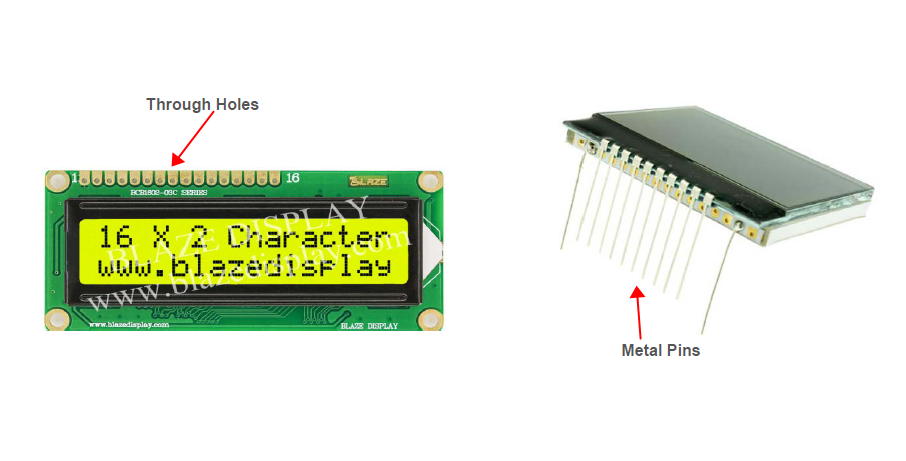

Through Holes

Through holes are a standard connection type for many displays that offer a connection through small holes on the PCB. This connection type is most common for LCDs that have an external PCB controller circuit mounted to the display, such as most character and segment LCDs. Typically, the PCB will include the required liquid crystal driver, a voltage converting circuit, and backlight control.

Through holes have conductive metal holes on PCB that can be connected to using solder or a bezel. A through hole connection gives many options for connecting and interfacing the display. Connecting the display via through holes is a good option for prototyping because the standard pitch between holes and wide range of options for connecting.

Through holes are not a good connection type for compact enclosures. They have a standard spacing that requires a hardwire solder connection or a bezel to hold the interface pins to the holes. However, this standard spacing is advantageous for hardware to plug into breadboard or peripheral devices.

Metal pins are a connection type for LCDs that have metal pins already mounted and connected to the display. Metal pins can be connected to the internal display controller or to the COM and Segment lines of an LCD. Typically, this connection type is used for character and segment LCDs.

The metal pins can be used for displays with or without an internal display controller. This makes metal pin displays a great option for prototyping. An external display controller can be used to control the liquid crystal through the COM and Segment pins directly. This enables the designer to choose the display controller based on their application.

Metal pins are a reliable, sturdy connection type that can be mounted into similarly spaced devices. They are accessed by plugging the display into a socket or by soldering the display into conductive holes on a PCB. Similar to the through hole connection type, metal pins are spaced to be compatible with breadboards for prototyping.

Metal pins are good for applications that have standard pin mappings so that the display can be plugged into the controlling device. This connection type is less versatile than the previous LCD connection types as the pins are hardwired into place and cannot be moved unless unsoldered. The standard distance between pins is 2.54 mm.

- Previous:Parity Bit

- Next:What is an LCD display module?